Group News: December 2015

BOP Panel System Upgrade: Total North Alwyn Platform

System Design, Manufacture, Assembly, ATEX Certification, In-house Testing & FAT.

Monitor Systems were approached by KCA Deutag RDS to design and manufacture a BOP control panel upgrade for the Total North Alwyn Platform.

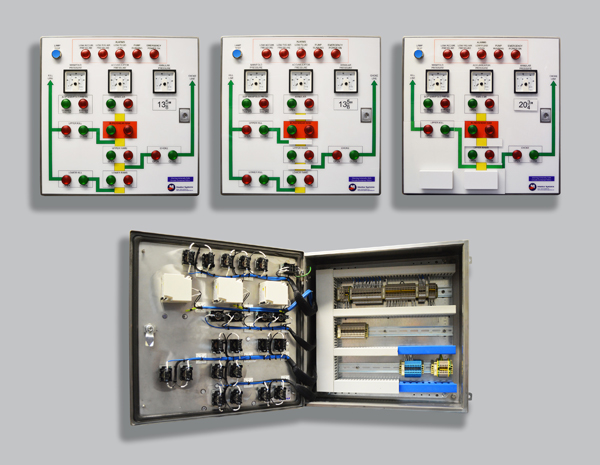

The BOP control panel upgrade incorporated a Drillers control panel, Lifeboat control panel, Toolpushers control panel and a Barrier enclosure.

Lifeboat’s BOP Control Panel. Made from 316 stainless steel, (1000 x 800 x 300mm) the enclosure was rated to IP66, (ensuring protection against water and dust). The control panel was designed and manufactured suitable for use in a Zone 1 area.

The BOP control panel features a number of illuminated pushbuttons, indicator lamps, meters and switches for functions such as choke, kill, upper/lower rams, shear rams, annular, annular & manifold pressure regulators as well as monitoring various alarm conditions, pressure and flow rates.

Driller’s BOP Control Panel. Made from 316 stainless steel, (1000 x 700 x 300mm) the enclosure was rated to IP55, (ensuring complete protection against water ingress). With the same facia design and controls as t.

he Lifeboat BOP control panel, the Driller’s BOP control panel features the same configuration of illuminated pushbuttons, indicator lamps, meters and switches for safe operation and control.

Toolpusher’s BOP Control Panel. Made from 316 stainless steel, (500 x 500 x 220mm) the enclosure was designed for Safe Area use only. With a similar graphical facia, the smaller BOP control panel also features a range of pushbuttons, indicator lamps for safe and efficient operation.

HPU Barrier Enclosure. Made from 316 stainless steel, (300 x 300 x 220mm) the enclosure was designed suitable for installation in Zone 2. The HPU Barrier enclosure contains the I.S (Intrinsically Safe) barriers to provide power & signal to the I.S Flowmeters.

Hazardous Area Classification. The Driller and Lifeboat BOP control panels were designed for use in Zone 1 (explosive mixture) gas environments.

The Toolpusher’s BOP control panel and HPU barrier enclosure were designed specifically for safe area use.

Facias / Graphical Overlays. All graphical overlays were reverse printed on polycarbonate. An additional graphic overlay was supplied for the Drillers, Lifeboat and Toolpushers control panel, giving the option to swap between 13 5/8” and 20 3/4” riser configurations. The addßitional overlays are easy to position and are secured automatically.