Sedco 704 Semi-Submersible Rig

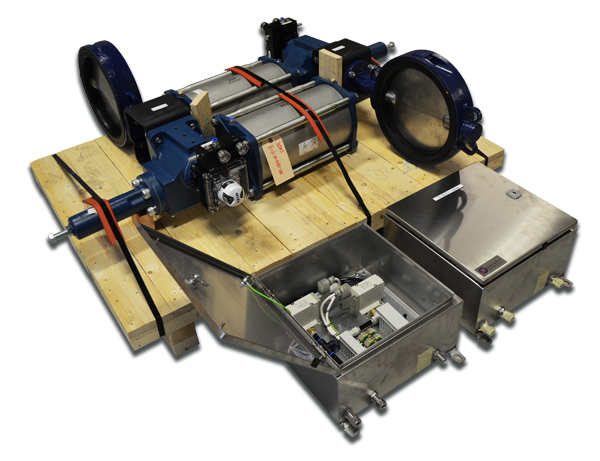

(BOD) Ballast Overboard Discharge Valves (ABS Approved)

Vessel Management System (VMS)

This Vessel / Marine Management System (VMS) was awarded to Monitor Systems as part of a major SPS project with the design and installation of a new Ballast Control Console and full associated Tank Gauging System to replace the old existing system.

The existing Ballast Control Console is the original panel installed when the rig was built and hence is quite basic. Monitor Systems have designed a redundant PLC based system that can monitor and control all ballast valves as well as monitor bilge levels throughout the rig. We can also monitor the Ballast Tank, Fuel Tank, Drill Water, Pot Water and Reserve Mud Tank Levels.

As part of the system we are supplying, the new Ballast Control Console will blend in with their existing control room layout. The new Ballast Control Console will be operated via seven 19” wide screen touch monitors built into the console. Monitor Systems are also monitoring the brace leak detection and ballast flow Bilge Valves and Sensors were also supplied to monitor the Bilge Pots. New Brace Leak Detection Sensors were integrated into the system to provide automatic monitoring of the leg bracings. The seventh display shows Environmental and Heli Deck Monitoring information.

Each of the 19" HMI IPC displays connect to the system’s datanetwork. A SCADA software package especially designed for the 704 has been installed on all display IPC’s and is operable through the display’s touchscreen interface. Provision has been made for an external mouse and keyboard to be plugged into each IPC. Alarm sounders, console lamps and a beacon installed in the control room will alert personnel to situations requiring operator intervention.

As part of the Tank Gauging System Monitor Systems are supplying 36 LevelCom liquid level computers pre installed on panels ready for connection to the tank piping. The Ballast Control Console will be connected to remote I/O panels throughout the rig utilising a redundant fibre optic network. Monitor Systems are also supplying new bilge valves and actuators and will be responsible for the full system installation.

Project Management of a new complete Fire & Gas System also falls under our scope of supply. Monitor Systems also supplied a UPS to power the Ballast Control System.

=A rapid & robust delivery schedule has been put forward to design and install the multi million pound contracts, all internally project managed at Monitor Systems.

Managing Director Brian Sinclair commented, ... "our engineering team and staff were all excited about this project; it comes on the back of other projects successfully completed and gives Monitor Systems the opportunity to show its strength, expertise and knowledge in this area."