Reverse Osmosis Watermakers

Monitor Systems are proud to be the exclusive European distribution partner for C’Treat Watermakers. Established in 1980, C’Treat provide innovative design and evolutionary development through field testing and combining the latest proven technology and advances in reverse osmosis. Monitor Systems can supply the most simple, reliable and economical low cost of ownership reverse osmosis watermakers for the offshore oil and gas industry. As a combined strength, Monitor Systems have factory trained engineers that install, service and commission reverse osmosis desalination watermakers 24/7/365.

A reliable, economical supply of fresh water for offshore installations

Monitor Systems Engineering - the most simple, reliable and economical watermakers for the offshore oil and gas industry.

Standard Monitor Systems Engineering systems (including pre-treatment, pumping and permeation sections) range in capacity from 4 to 100m3/day (1000 to 22,000 USgpd). In addition, Monitor Systems Engineering can design and build custom water treatment systems of larger capacities to meet specific customer needs.

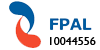

Based on extensive experience, the simplicity of Monitor Systems Engineering watermakers allows for easy operation and maintenance in demanding offshore marine environments. Unique system technology provides excellent reliability, economy and constant water production without using chemicals.

Our Services

Monitor Systems Engineering service is to provide its customers with reliable and economical supplies of fresh water, generated from seawater using the reverse osmosis process, and is committed to increasing customer satisfaction through continual improvement of this service. Monitor Systems Engineering has build a reputation for delivering high quality, innovative integrated water systems solutions for the offshore oil & gas industry.

Monitor Systems Engineering integrated water systems are easily operated and maintained by offshore personnel. The improvements we continue to make allow greater capability for doing all normal maintenance offshore, with reduced dependence on onshore specialists.

Global Operations

Monitor Systems Engineering considerable experience in offshore desalination has been extended to include integrated water treatment and handling systems for offshore installations. Monitor Systems Engineering has provided seawater and freshwater filtration, pumping, and storage packages; ultraviolet and chlorine sterilization packages; and completely custom engineered water systems for customers around the world.

Reverse Osmosis Watermakers and Systems

Reverse Osmosis Watermaker Systems and Solutions from Monitor Systems Engineering meet the most demanding applications in harsh environments.

Reverse Osmosis Watermaker Desalination Systems for Offshore Applications

Monitor Systems Engineering builds a range of Reverse Osmosis (RO) watermaker systems to meet the wide variety of demands of the offshore drilling and production industry. Each packaged system is designed and built for simple operation and ease of maintenance. The system components have been selected, developed, or and optimized for use in the offshore environment.

Monitor Systems Engineering produces both standard and custom Reverse Osmosis Watermaker Systems.

Our world-wide reputation as the premier supplier of potable water RO Watermakers to offshore oil & gas production facilities is founded on the standard ''FD'' Series Watermakers. Potable water RO Watermakers from Monitor Systems Engineering can provide water production at rates from 4 to 100 m3/day.

Custom Reverse Osmosis Watermaker solutions from Monitor Systems Engineering have been designed to produce many other kinds of water including: Boiler Feed, Turbine Wash, Battery top-up, and the higher capacity demands of Crude desalting, and Well Injection.

FD Series Reverse Osmosis Watermaker Design Features

• Four stages of graded mechanical filtration, including:

- 3 x 50%, activated carbon, media filters, automatically backwashed with the reject brine and with no interruption to fresh water production.

- Three more stages of bag and cartridge filtration to 1/2 µ

• The Series 20, single-stage centrifugal, RO pump with over 30 years of operation in the offshore environment. A pump with no vibration and quick and easy to repair offshore.

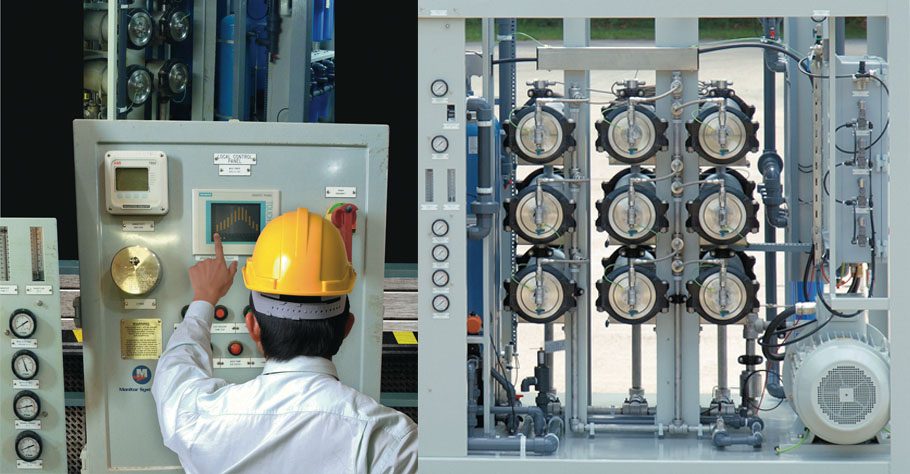

• The Type 200-SWHR permeators with one membrane element per housing; sample valve, vent seals; by-pass shunt; quick access end cap; galvanically protected 316L and Nitronics® construction.

• Net Osmotic Pressure Controller (NOPC) for membrane flux control.

• Brine pressure let-down tubing for RO pump flow & pressure control.

• Rugged steel frames with high quality epoxy coatings

• Corrosion resistant and durable components

• Compact footprint

• Highest levels of filtration in the industry

• Simple, reliable, and most economical system

Because the offshore marine environment is so severe, reliability depends on systems which can withstand the test of time. For twenty years Monitor Systems Engineering equipment has been providing dependable fresh water for drinking, equipment wash-down, general utility, desalting crude, and other processes. Monitor Systems Engineering has been rejecting unreliable components and integrating only field proven components into standard designs. This sustained work over many years has resulted in highly reliable, economical Reverse Osmosis desalination plants for offshore marine installations.

Steel-Cage Frame Construction

Potentially the most destructive forces on a watermaker occur as it is shipped and moved into place, and when it is damaged by other on board equipment, such as a crane or forklift. Monitor Systems Engineering’s steel cage construction protects the components from this sort of unpredictable damage.

Shippers have dropped heavy skids on top of our units in the past, but the rugged, steel cages enclosing the components have allowed the equipment to suffer only minor damage and go on to operate successfully with little or no repairs needed.

System Details:

Graded Mechanical Filtration

- Filters raw seawater down to 0.5 microns

- Protects and extends the life of membranes

- Provides the cleanest seawater practical to the system

High Pressure Reverse Osmosis Centrifugal Pumps

- Only one rotating part makes for high reliability

- Technology eliminates over pressurisation problems

- Easily maintained and quickly serviced

Field Serviceable Permeators

- Simple service condition monitoring of membrane cartridges

- Quick and easy access to cartridges

- Servicing can take place whilst water-making continues

Specialised Construction Techniques

- Rugged steel cage construction fully protects unit and components

- Seal welded joints and type 316 stainless steel fittings protect against corrosion

- Three coat marine paint system provides maximum structural protection

Cost and Reliability

- Measured by the cost per gallon produced, the most economical desalination system available

- Field proven for high reliability (many systems operating continuously since 1982

- Constant water production without using chemicals

Worldwide Installations

- Monitor Systems Engineering watermakers installed on every major type of drilling installation in field of offshore production

- Approximately 50 million gallons a year produced from 40 C'treat systems for West Africa offshore operators

- Beyond the continental shelf, C'treat produce over 10 million gallons of fresh water a year for production platforms

Aftercare and Customer Support

- Readily available consumables and spare parts

- Maintenance training for offshore personnel

- Problem solving assistance

- Maintenance and servicing