Rig Stacked Remote Monitoring

History shows us that the decline in oil prices over a sustained period of time is the primary contributing factor for oil drilling contractors to set about 'cold stacking' rigs. The secondary factor is the cyclical downturn in demand for a given rig type.

Many oil contractors look at 'warm stacking' prior to 'cold stacking' rigs, as they hope that the market will turn around quickly, however in a sustained period of reduced oil prices, cold stacking is sometimes the only economical and viable solution until there is a significant recovery.

Cold stacking rigs inevitably means that workers are let go and the rig is completely shut down. Cold stacking a rig involves reducing the crew to either zero or just a few key individuals and storing the rig in a harbor, shipyard or designated area offshore.

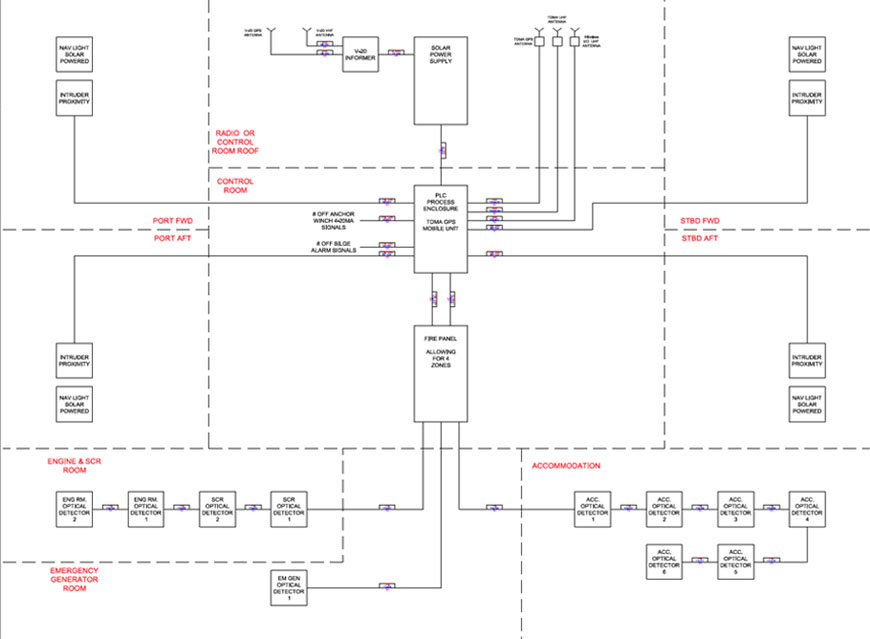

Typically, steps are taken to protect the cold stacked rig including the installation of monitoring systems that communicate rig status and critical systems information to locations onshore. Monitor Systems provides a comprehensive marking and monitoring system that can include GPS Position Monitoring, Intruder Monitoring, Fire and Bilge Alarm Monitoring, Anchor Winch Tension Monitoring, (AIS) Automatic Identification System, all powered by a solar power supply.

Scope of Work: The marking and monitoring of cold stacked rigs involves the following 'scope of work', Project Management, Conceptual Design, QA & HS&E Management (ISO 9001 Compliant), Engineering and Manufacture, System Testing and Software Interrogation. System Documentation (two hard copies and online transfer) is also included.

System Overview: The cold stacked rig is ‘marked’ by the use of navigational obstruction lights and the rigs positon is monitored and relayed to a monitoring station in the Port Authority’s Office. The stacked rig is also fitted with an Automatic Identification System (AIS) transmitter which transmits its position every three minutes. As an option, Monitor Systems can include this to be monitored in the Port Authority Office.Our marking and monitoring system can monitor the bilge alarms, anchor winch tensions, fire alarms, intruder monitoring and any other required signals, with signals marshalled into a local process enclosure and terminated onto a wireless I/O module to be transmitted over UHF. The hardware fitted to the unmanned rig is powered by solar/ wind power and is fully operational 365 days per year.

SYSTEM DETAIL:

Rig Position Monitoring: The system transmits the positional data from the cold stacked rig to the base station located in the Port Authority’s Office. The GPS position is monitored and the rigs position is displayed on the SCADA Software. Alarm set-points can be configured in the system so that should the cold stacked rig move out of its designated position, the alarm is activated.

Intruder Monitoring: Sensors can be provided for installation at key points around the rig to detect any unauthorised entry. These signals will be relayed back to the wireless I/O module which will monitor the inputs. Again should any of these sensors be activated an alarm will be sounded in the Port Authority’s Office.

Fire Monitoring: The system can be set to monitor key areas on the vessel, these areas include, but not limited to; Engine Room, SCR Room, Emergency Generator and Accommodation area.

A standalone Fire System or the existing Fire Detection System can be utilised, however using the existing Fire Detection System would impact on the size of solar power required.

Bilge Alarm Monitoring: Sensors can be installed to monitor the cold stacked rig’s pontoons, offering a continuous automatic monitoring of the rigs watertight integrity. Leak Detection Sensors can be easily retro fitted into braces, bilge pots or void spaces to monitor for complete vessel watertight integrity.

Anchor Winch Tension Monitoring: The system can monitor the tension of all anchor winches on the cold stacked rig. The anchor winch tensions can be displayed in the Port Authority’s Office and alarm set-points configured so an alarm is sounded when hi or low tension is detected. These signals will be wired back to the wireless I/O module.

AIS: Automatic Identification System: This system can provide positional information for the rig and warn any other vessels in the area equipped with an AIS system of danger to navigation.

The position of the vessel is gained via GPS, but the communication between the base station and other vessels is over VHF.

Our Type 1 AIS AtoN is a transmit only device using the FATDMA (Fixed Access Time Division Multiple Access) access scheme. This mode of operation therefore requires that an AIS base station is operating in the same area as the AIS AtoN and is configured to make the necessary slot reservations. The base station canl be installed in the Port Authority’s Office.

Solar Power Supply: As previously mentioned the system will be powered with a Solar Power Supply. The power supply will be sized to requirements, allowing continuous operation through the year. The battery supplied with the system will be sufficient to power the system for 30 days with no additional charge from the solar panels.

Solar Powered Marine Lanterns: The rig can be fitted with Solar Powered Marine Lanterns. They come with White LED’s and provide a 30 second Morse code U signal. The units used in our system can be viewed for 3.5 miles.

The unit features unique and proprietary optics which provide a 360° beam at 5°, 10°, 20° or 30° vertical divergence. Utilising a highly efficient compact lens, the unit is engineered to utilise the advanced and cost-effective technology of LEDs. Solar modules and high-grade batteries are housed in a compact self-contained marine lantern, designed for low maintenance with a projected service life of 10 years before any significant maintenance is needed. The 5° and 10° divergence lenses are ideal for fixed or floating aids to navigation while the 20° or 30° lens provides exceptional performance on buoys. The 5° lens can be used to meet specific needs that require a much longer range while still using a minimal amount of power.

Port Authority’s Office: The Port Authority’s Office canl be fitted out with a PC complete with two Monitors. One monitor can be used to display the AIS Informer Data. Using Siemens software the second monitor can be used to display rig location monitoring along with the anchor winch tension monitoring, fire alarm monitoring, brace / void leak monitoring and Intruder Detection monitoring.

There will be a local Siemens PLC which will be used to process the ASCII string from the High Accuracy GPS Base Station and the I/O from the Wireless I/O unit. The PLC will be connected to the above PC over Ethernet.