Tank Gauging Sensors / Tank Level Gauges

Marine and Offshore / Process Control / Water Well and Environmental Level Monitoring Systems and Applications

Monitor Systems is the exclusive UK distributor for TMS LevelCom Tank Gauging Sensors (Tank Level Gauges). TMS LevelCom is the leader in designing and manufacturing continuous level measurement gauges using hydrostatic pulsed bubbler technology for measuring and monitoring a wide variety of liquids in marine and Industrial applications.

For reasons of accuracy, dependability and competitive pricing, Monitor Systems uses LevelCom tank level indicators in its ballast tank gauging systems as well as supplying the equipment as stand alone monitors.

Featuring 'Smart Bubbler Technology', the system combines microprocessor technology with the proven accuracy of a bubbler for sensing fluid depth. Whilst most competitors products can supply an analog signal for measurement, this is one of the only level sensing systems that communicates system status, provides control relays for other equipment, has alarm functions, analogue outputs, and Modbus or Profibus communication.

The Tank Level Indicators have a wide range of applications and better versatility than most other tank level gauging sensors. It is also accurate and reliable with problematic, corrosive, acid or foaming fluids, low viscosity fluids, suspended solids, variable specific gravity and temperature variations, as it is with standard liquids.

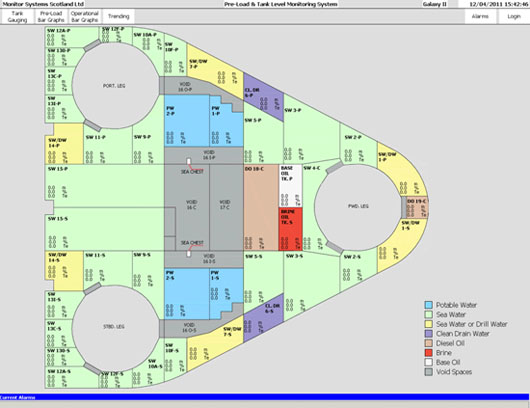

Marine and Offshore Applications

Tank Level Indicators

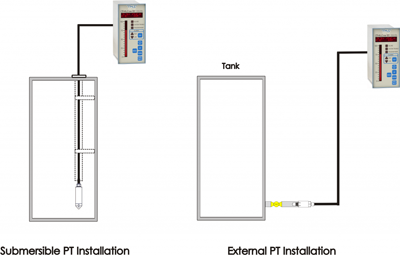

Overview: The Tank Level Indicator utilises pulsed pneumatic (bubbler) depth sensing technology and resolves the problems long associated with continuous flow bubblers. The Tank Level Indicator is engineered to meet the demands of offshore marine applications and environments by incorporating computer technology with state of the art features into a microprocessor-based tank level indicator. The Tank Level Indicator combines automatic leak and plugged line detection with automatic “hardware zero” that compensates for pressure differentials. If an abnormal condition is detected, the Tank Level Indicator will display the appropriate error message on the digital display and/or provide the data on the communication bus to alert the operator.

The Tank Level Indicator is an integral part of the tank gauging systems installed on many offshore rigs both semi-submersible and jack up, supply vessels, ships and barges. The LevelCom Tank Level Indicator represents significant cost savings over most other type of tank level indicators when replacing or upgrading. In bulkhead tanks LC-100′s maintain system integrity as the tank shape does not impact the LC-100 and its ability to make accurate readings. The automatic specific gravity option is primarily to indicate level on mud tanks.

Offshore applications include:

• Semi Submersible Drilling Rigs – Rig Stability Monitoring System

• Jack Up Rigs – Preload System

• Supply Vessels – Ballast Tanks, Fuels, Additives

Depending on the system configuration and the type of tank, the Levelcoms can be programmed to give various alarm signals, such as tank high or low or can be programmed for engineers alarms to alert the operator of a critical conditions.

LevelComs configured with MODBUS or Profibus options can display the tank level information, alarms and controls on a monitor, HMI or Touch Screen in the control room or other onboard location.

Process Control Applications

The Leader in Solving Problem Fluid Applications

Overview: The LC series pulsed bubbler is one of the most versatile technologies available in continuous level measurement with more capabilities and functions than most other tank level monitors on the market!

The LevelCom LC-100 Tank Level Indicator excels in applications that are problematic for other level measurement sensors. The LC-100 provides continuous level measurement in water, aqueous solutions, hazardous and corrosive liquids with varying viscosities, temperatures and specific gravities along with applications where radar, ultrasonic, float or microwave level sensors have proved undependable or where the fluid properties and tank environment cause premature sensor failure.

The LevelCom Junior (LC-101)

The LevelCom Junior LC-101 is a bar graph display is specifically made for tank level gauging. The Junior has much of the same functionality as the LevelCom LC-100 bubbler but works with Pressure Transducers, Capacitive, and Ultrasonic level sensors measuring the 4-20 mA analog signal from the sensor and communicating externally via Modbus. The Junior has a six character digital display combined with a 40 segment bargraph, reads in depth, volume or mass; has alarms, status lights, and push button panel for programming the configuration interface.

The LevelCom Junior is self-diagnostic and can detect hardware errors like a failure of the sensor signal, or loss of the digital communication signal in the case of a digital repeater. If an abnormal condition is detected, the LevelCom Junior will display the appropriate error message on the digital display and activate an alarm to alert the operator.

The LevelCom Junior includes three relays. Two relays have form “C” contacts and can be configured for either alarm or control functions. The third relay has a single form “A” contact and is intended to drive a warning horn for local alarm indication.

The Junior can work as a stand-alone unit or can be panel mounted in multiples to meet the applications requirements. The LC-101 also functions as a digital repeater for the LevelCom LC-100 bubbler.

Water Well and Environmental Level Monitoring Systems

LC-300 Well Level Gauge

LevelCom LC-300 Well Level Monitor: Developed to meet the industry’s needs for accurate, cost effective and dependable water level monitoring, the LevelCom 300 eliminates the problems associated with traditional pressure sensors and cables in down hole applications. The LevelCom 300 Well Level Monitor incorporates the accuracy and proven technology of a bubbler with a full compliment of SCADA capabilities to give you the best features in liquid level gauging.

Some features of the LevelCom 300 are:

• 20 – 2000 foot depth range

• Timing of sample cycles

• Manual input of specific gravity

• Four alarm setpoints with hysteresis

• Analog and/or digital outputs

• Wireless Communication to LAN or Spread Spectrum RF

• Calibration verification - the sensor is connected to the bottom of the well by a gas filled bubbler tube, not at the bottom of the well

• Measures wellhead pressure eliminating errors from using multiple sensors for this measurement.

Self Diagnostics - detects hardware errors, sense and supply line problems including leaks, plugged lines and low supply gas pressures and communicates them via the display.

Modbus interface provides plug and play to data telemetry systems allowing remote read out of well level.

Simple 3 step installation; power hook up, connection to a sense tube in the well and a clean high-pressure nitrogen gas cylinder. Depth in English or metric units.

System Details:

Design and Build

- Robust, proven design and manufacture / Made for tough offshore, marine and industrial use / Accuracy, dependability and long service life / Self diagnostic / detection of hardware problems

Display

- Specific to tank level monitoring / Clear digital data, alarms and controls / Easy to understand and use

Measurement and Control Capability

- Depth, weight and volume / Specific gravity / Differential pressure / Detects supply line problems, leaks, plugged lines and low supply pressure

Operating Versatility

- Standard liquids / Corrosive solutions, acids and foaming fluids / Suspended solids and low viscosity fluids / Wide ranging temperature variations / Works in any tank shape

Operating Systems Options

- 0 to 55 metres range / 120 VAC, 240 VAC and 24 VDC power input / RS 422/232 Modbus, Profibus or Devicenet / Analog output 4-20 mA

Range of Applications

- Rig stability monitoring / Fuel, mud and additive tanks / Ballast Tanks / Fuel Oil Management / Wastewater / Distilled & Potable Water / Viscous Fluids / Drill Mud / Hazardous Substances / Hull Draft Indicator

LC-100 Features

- Robust, Proven Design / Field Configurable / Multiple Set Points / Control capability – Integrates with third party controllers, data acquisition systems and software / MODBUS Connectivity (Devicenet & Profibus Available)

- Specific Gravity / Differential Pressure / Output Control Relays / Depth, Weight, Volume / Works in any shape tank / ABS Type Approval / UL Listed / Long Service Life

Benefits and Key Features of “Smart Bubbler Technology

- Unaffected by corrosives, caustics, acids, slurries and temperature / Allows for placement of the controls away from tank and harsh or hazardous environments / Level, weight and volume display (English / Metric)

- Field configurable with High and Low alarm functions, multiple set points and specific gravity corrections / Diagnostic capabilities detect leaks, plugged lines, pressure problems, and hardware errors.

- Modbus connectivity standard with Profibus available / 110VAC, 220 VAC and 24VDC power supplies standard / Network Capable, Integrates with SCADA systems

- Control relays can be set to activate variable frequency pumps and other devices / Easy and inexpensive installation - refit / Up to 70% less than radar sensors / UL Approved

Partial list of industries that currently use LevelCom technology

- Silicon Foundries & Wafer Manufacturers / Advanced Ceramics Processing / Building Products

- Mining / Defense / Municipal Water Districts / Landfills / Wastewater Treatment / Oil & Gas /Agriculture

LC 101 Key Features

- Displays accurate volume and weight; depth in feet & inches / 40 segment bar graph displays tank level and alarm set points / Programmable alarm & control points

- Integrates with Data Systems / RS422 /485 Modbus connectivity / Complete self diagnostics / Three analog inputs allow density & pressure compensation / Long service life / Small Footprint

- Wide range of applications / Easy installation / UL approved